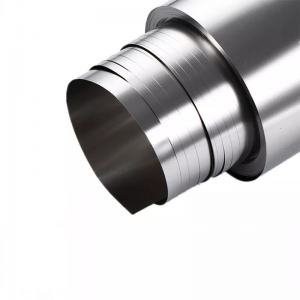

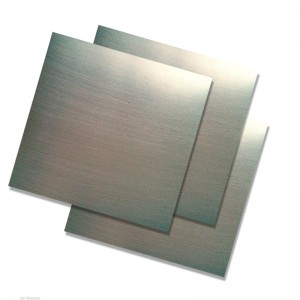

Hastelloy S nickel round bar, UNS N06635 nickel plate

▪ AMS 5711

▪ AMS 5838

▪ AMS 5873

Hastelloy S has good machining characteristics. Tooling is required to avoid work hardening and chatter.

Hastelloy S can be formed using conventional methods.

Hastelloy S is welded using metal inert gas and tungsten inert gas welding methods.

Hastelloy S is heat treated by annealing at 1066°C (1950°F) followed by cooling in air.

Hastelloy S is forged at 872 to 1149°C (1600 to 2100°F).

Hastelloy S can be hot worked at 872 to 1149°C (1600 to 2100°F).

Hastelloy S can be easily cold worked.

Hastelloy S is annealed at 1066°C (1950°F) followed by cooling in air.

Hastelloy S is aged at 538 to 872°C (1000 to 1600°F) in order to restores its ductility and strength.

Hastelloy S can be hardened by cold working.

Hastelloy S is used in gas turbines.

| Elements | Content (%) |

| Nickel, Ni | 67 |

| Chromium, Cr | 14.5 - 17 |

| Molybdenum, Mo | 14 - 16.5 |

| Iron, Fe | 3 |

| Cobalt, Co | 2 |

| Tungsten, W | 1 |

| Copper, Cu | 0.35 |

| Manganese, Mn | 0.30 - 1.0 |

| Silicon, Si | 0.20 - 0.75 |

| Aluminum, Al | 0.10 - 0.50 |

| Carbon, C | 0.020 |

| Phosphorous, P | 0.020 |

| Boron, B | 0.015 |

| Sulfur, S | 0.015 |

| Lanthanum, La | 0.010 - 0.10 |